Water-cooled screw chiller

Air-cooled screw chiller

Industry-specific (industrial) chiller

Box (closed) industrial chille

Low-temperature chiller unit

Water-cooled scroll bench open chiller

Air-cooled scroll chiller

Air-cooled screw (scroll) heat pump unit

Explosion-proof chiller

Closed cooling tower

Open cooling tower

Low-temperature chiller unit

Position:

Home > en > Products > Low-temperature chiller unit >

Medium and low temperature screw chiller

Number of products: 1614134816

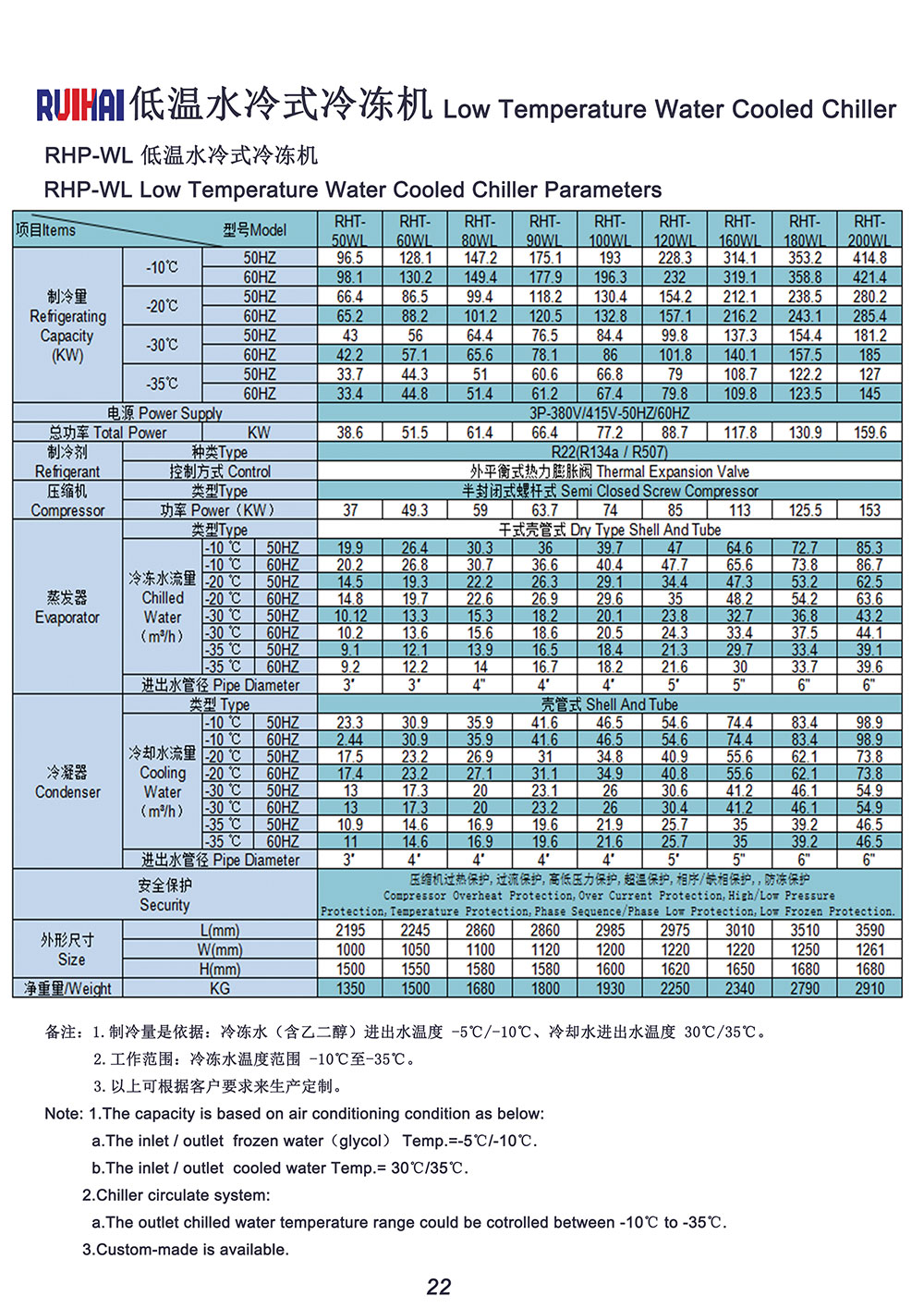

Specification: RHT-WL

Product Features

Low temperature chiller has the advantages of high efficiency, low noise, long life and easy operation. It can provide complete sets of process cooling low-temperature water for chemical, pharmaceutical, food, grain processing, fruit processing and other industries, and can provide low-temperature and low-temperature frozen aqueous solutions at -5 ° C ~ -35 ° C.

Product features

Low temperature chiller has the advantages of high efficiency, low noise, long life and easy operation. It can provide complete sets of process cooling low-temperature water for chemical, pharmaceutical, food, cereal processing, fruit processing and other industries, and can provide frozen low-temperature water solutions at -5 ° C ~ -50 ° C.

Second, the unit characteristics

● Stable and reliable operation, high efficiency and energy saving

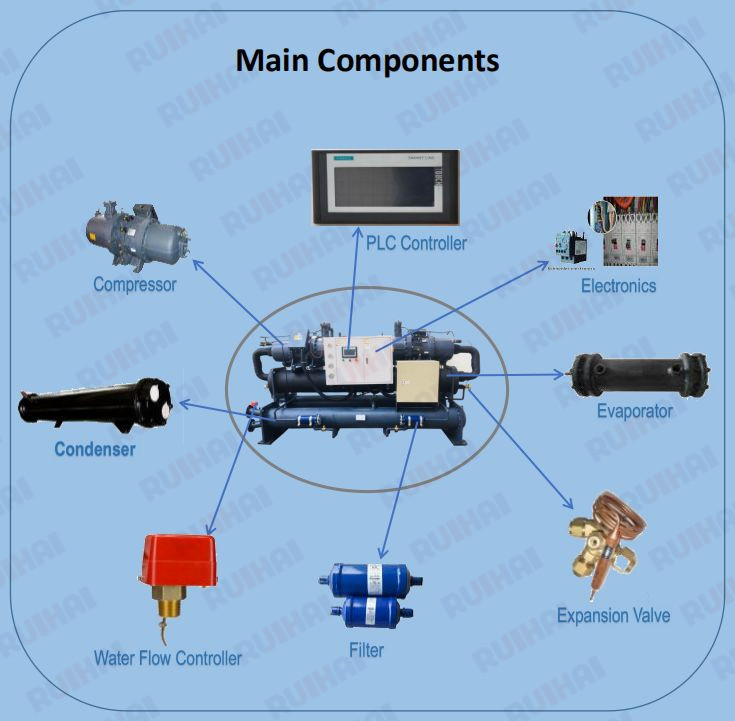

The refrigeration compressor uses a well-known brand semi-hermetic screw compressor. Its rotor is an internationally advanced 5 / 6-tooth design with built-in suction filter, oil filter, oil separator, safety pressure reducing valve and protection module. Leakage, low noise and stable operation. The high-efficiency shell-and-tube heat exchanger is used as the condenser and evaporator of the unit. All the control components adopt well-known brands and a number of safety protection functions, which make the unit operate safely, reliably, and efficiently. Multiple compressor units use multiple refrigeration circuits. When one of the compressors fails, the remaining circuits can still work normally.

● Multiple refrigerant options

Applicable to R22 refrigerant, and can also use environmentally friendly working fluids such as R407c and R134a according to user requirements.

● The unit runs smoothly with low noise

Because the compressor lubricating oil is supplied by high and low pressure differential, and the built-in oil not only has a high oil separation efficiency (99.99%), but also can absorb the noise of the unit, the unit runs smoothly and has low noise.

● High degree of automation, simple and convenient operation

The advanced microcomputer automatic control system is adopted, which can precisely control and perfect the protection of the unit through the touch screen. The interface can display the unit operation status, parameter setting values, alarm conditions and records, etc., so that the operator can see at a glance, the operation is very simple and convenient. It has interlocking control function with refrigerant water pump, cooling water pump and cooling tower fan. In addition, you can configure powerful communication functions according to user needs, and realize remote monitoring and fault diagnosis of single or multiple units in different cities or regions through the telephone network or the Internet.

● Simple on-site installation

For the installation of low-temperature chiller, it is only necessary to connect water and electricity on site and charge a proper amount of refrigerant, and it can run after debugging, eliminating the need for a lot of on-site installation work using traditional bulk salt water equipment.

Water system piping

1. The inlet and outlet water pipes and valves of the unit should be properly insulated to avoid the loss of cold energy and the occurrence of condensation.

2. In order to ensure that there is sufficient water in the evaporator, condenser and piping system, a water flow switch should be installed on the water outlet side of the evaporator and condenser, and it should be controlled in chain with the compressor. In order to avoid the phenomenon of internal freezing due to lack of water in the evaporator, low pressure is too low, poor oil return to the system or high condensation pressure, resulting in high pressure protection.

3. When multiple heat exchangers are used in parallel with the chiller, in order to keep the water flow of each heat exchanger the same and prevent the phenomenon of partial flow, the resistance of the piping from the chiller to each heat exchanger must be equal.

4. When the closed loop water system is used, the expansion or contraction of the buffer water volume and the effect of the isolation supply water pressure on the water piping. An expansion water tank should be installed at the return water of the unit. Need to be higher than 1 meter.

5. The cold water pump of the chiller should be installed on the inlet side of the evaporator.

6. In order to avoid air trapped in the water system, automatic exhaust valves should be equipped at the local setting points of the water piping, and the water pipe should be constructed at an inclination of 1/250 upwards. Before installation of the water system pipeline, it should be derusted, clean and free of welding slag. The unit must be kept clean until it is put into operation.

7. The water outlet of the water piping should be equipped with a shock-proof hose to prevent the vibration of the body from being transmitted to the room through the water pipe.

8. Thermometers and pressure gauges should be installed at the inlet and outlet of the unit to facilitate inspection and maintenance during daily operation.

9. When the ice water machine is running, the water flow or non-freezing liquid flow in the evaporator must be kept above the minimum flow.

10. The water inlet and outlet piping accessories should be equipped with a socket to facilitate easy separation from the water piping during maintenance.

11. The weight of the water pipe must not be borne by the machine body. When the water inlet and outlet of the pump set are connected to the corresponding water pipe, they should be isolated by shockproof water pipes or rubber joints to avoid the transmission of vibration and noise and mutual interference.

12. The chiller condenser and cooling water piping are recommended to be piping as shown in Figure 1.