Unit functions:

The unit can provide low-temperature refrigerants of ethylene glycol aqueous solution with a certain concentration from 0 ℃ to -60 ℃, and a variety of refrigerants can also be selected. According to customer requirements, CaCl2 aqueous solution, ethylene glycol aqueous solution, and ternary mixed solution (40% Ethylene glycol, 40% water, 40% ethanol), R22, and other approved refrigerants. The evaporator can also be designed according to anti-corrosion requirements. Calcium chloride aqueous solution is used as the refrigerant. Places required by low-temperature cold sources, such as reaction kettles in the pharmaceutical and chemical industries, large-scale cold storage, beverage and food industries, wine industry, and ice rinks.

Unit characteristics:

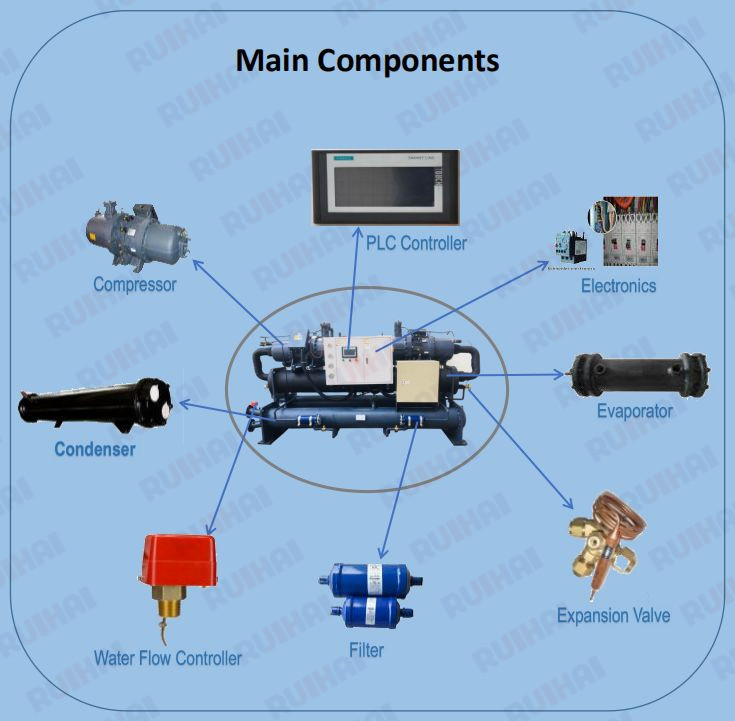

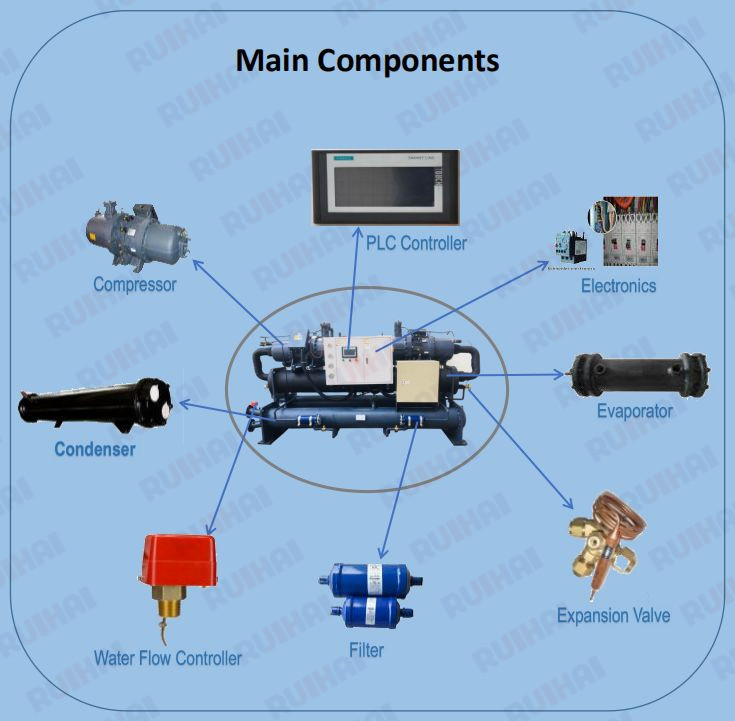

compressor

Internationally renowned brand screw refrigeration compressors, US and European patented technology

High-efficiency 5: 6 third-generation asymmetrical toothed screw of the most advanced line

Semi-closed design with only three moving parts, featuring low parts count and low failure rate

It can realize gradation or stepless energy adjustment, flexible and convenient control, energy saving, high efficiency and easy maintenance.

World-renowned SKF and FAG zero-gap multiple thrust and radial bearings are used for precise structure and high reliability

Three-stage oil separation filter, with good oil filtering effect, effectively guarantees the normal operation of the compressor and the efficient heat exchange of the heat exchanger

Use pumpless built-in differential pressure oil supply and lubrication system, energy saving, efficient and reliable

Dedicated fluorine-resistant low iron loss motor design, equipped with reliable motor overheat protection device, effectively guarantee the efficient and reliable work of the motor

Equipped with a liquid refrigerant injection system under low temperature and heat pump conditions, effectively reducing the workload and exhaust temperature of key components, and improving the reliability of the compressor

Patented exhaust chamber design and continuous rotor air delivery ensure low vibration and low noise of the compressor

Exhaust check valve installed at the exhaust port prevents the rotor from reversing during shutdown

Water-cooled condenser

The washable water-cooled condenser adopts a reinforced heat exchange tube (internal ribs on the outer fins), which is connected to the tube sheet. To ensure the safety of the equipment.

Hydraulic control valve

The imported ball valve can effectively reduce the resistance of the refrigerant liquid pipeline; at the same time, when the filter is dirty, it is convenient to replace the filter element and clean the filter cylinder.

Dry filter

Adopt welded angle filter, the filter element is imported molecular sieve. Can filter water, acid and other impurities, and easy to replace.

Expansion valve

The imported thermal expansion valve is used to throttle and reduce the low-temperature and high-pressure supercooled liquid to low-temperature and low-pressure liquid, and automatically adjust the flow of refrigerant into the evaporator according to the evaporation temperature, and maintain a certain pressure, thereby ensuring Evaporation rate.

Economizer

The imported plate heat exchanger is used to further increase the subcooling of the refrigerant, increase the cooling capacity, and change the single-stage compression to a quasi-two-stage compression, which improves the efficiency of the compressor itself. The configuration of the economizer improves the cooling efficiency and reduces the operating cost of the unit.

Electrical control system

The main parts are imported to ensure the reliability of the unit operation. Unit control adopts PLC touch screen control to make operation easier.

After-sales service:

The warranty period is 18 months, free maintenance during the warranty period, only the material cost fee is charged outside the warranty period, and lifetime maintenance.