Water-cooled screw chiller (single head)

Number of products : 71711263416

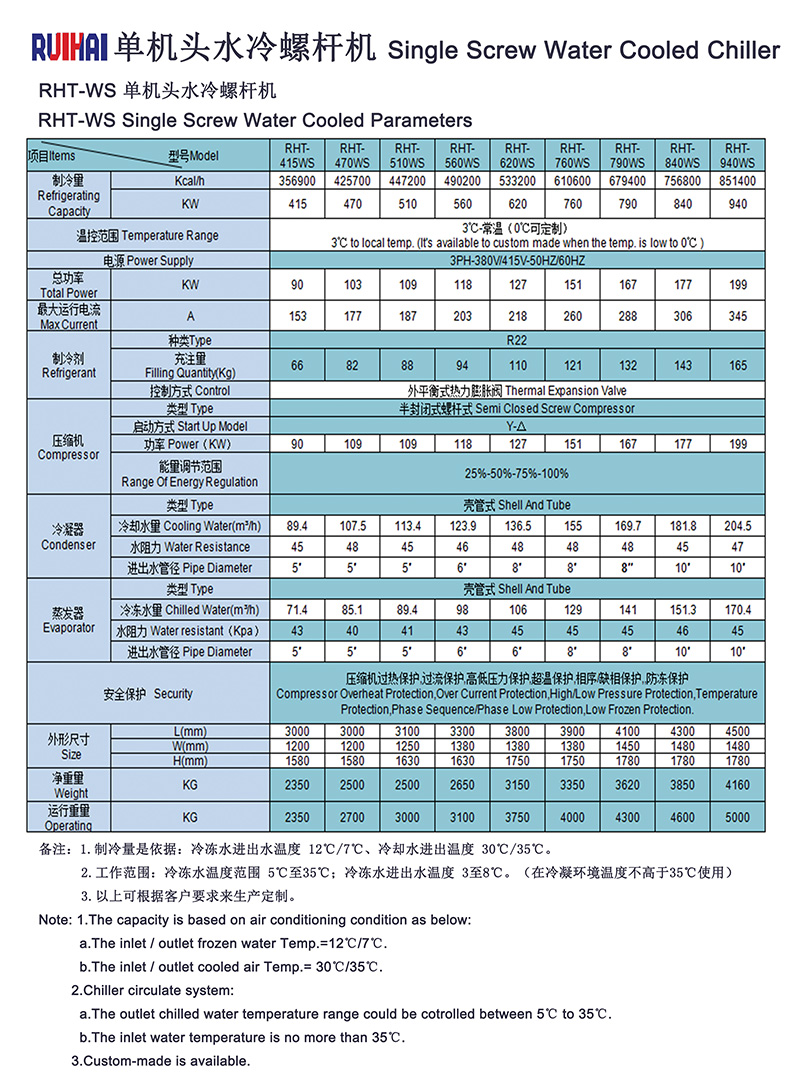

Specification: RHT-WS

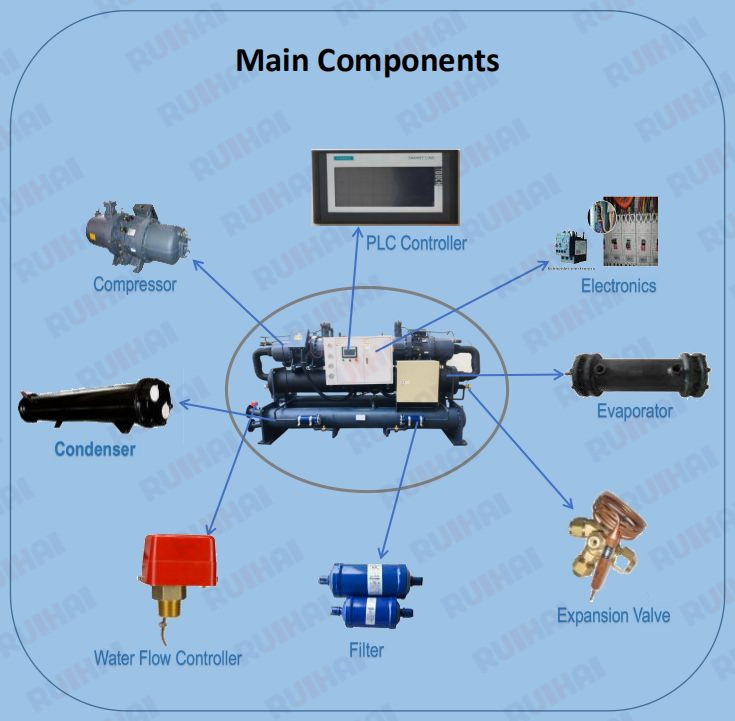

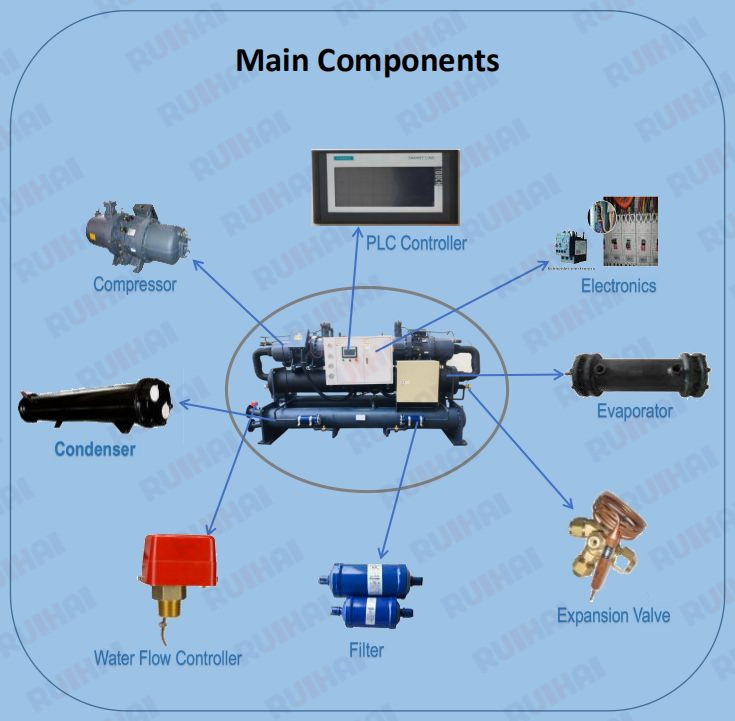

1. The unit adopts a semi-enclosed high-efficiency screw compressor with built-in safety protection, low noise, power saving and durable

2. High-efficiency shell-and-tube heat exchanger, using the latest technology, small size, high performance, not easy to damage, built-in high-pressure liquid reservoir to achieve no loss in the system and ensure smooth oil return

3. The chiller condenser adopts water cooling method, which can be used on various systems, not limited by the ambient temperature, stable performance and convenient maintenance.

4, equipped with a single-chip microcomputer control system, built-in compressor dryer filter and expansion valve, maintenance hand valve interface and other devices to ensure reliable and safe operation of the machine, convenient maintenance and repair.

5. Equipped with liquid injection system can effectively reduce the compressor oil temperature, which greatly improves the efficiency of the unit under low temperature conditions.

6. The imported PLC man-machine operation interface is LCD touch screen, graphic display, convenient operation, Chinese and English optional. Equipped with RS485 national standard communication interface, it can be connected to DCS system, and can be connected to the entire factory automatic control network for remote control and monitoring.

Features of single head screw type unit

1. The unit uses a semi-enclosed high-efficiency screw compressor with built-in safety protection, low noise, power saving and durable.

2. High-efficiency shell-and-tube heat exchanger, using the latest technology, small size, high performance, not easy to damage, built-in high-pressure liquid reservoir to achieve no loss in the system and ensure smooth oil return

3. The chiller condenser adopts water cooling method, which can be used on various systems, not limited by the ambient temperature, stable performance and convenient maintenance.

4, equipped with a single-chip microcomputer control system, built-in compressor dryer filter and expansion valve, maintenance hand valve interface and other devices to ensure reliable and safe operation of the machine, convenient maintenance and repair.

5. Equipped with liquid injection system can effectively reduce the compressor oil temperature, which greatly improves the efficiency of the unit under low temperature conditions.

6. The imported PLC man-machine operation interface is LCD touch screen, graphic display, convenient operation, Chinese and English optional. Equipped with RS485 national standard communication interface, it can be connected to DCS system, and can be connected to the entire factory automatic control network for remote control and monitoring.

7. Automatically detect the water temperature or return water temperature. By controlling the compressor capacity and adjusting the slide valve, the cooling capacity of the unit is automatically adjusted, which makes the operation more energy efficient.

8. Automatically record the first 20 fault alarm points, which is convenient for maintenance personnel to judge and repair the unit in time.

9, low noise, small vibration, designed according to industry standards, suitable for 24 hours a day operation.

10. The whole machine has stable running parts, extremely low maintenance cost and long service life.

Application range

Can be widely used in plastics, electroplating, electronics, chemicals, pharmaceuticals, printing, food processing and other industrial refrigeration processes that require the use of frozen water, or large-scale shopping malls, hotels, factories, hospitals and other central air-conditioning projects that require refrigeration Water central cooling area.

After-sales service:

The warranty period is 12 months, free maintenance during the warranty period, only the material cost fee is charged outside the warranty period, and lifetime maintenance.