International first-class accessories and technology

1. The unit adopts a fully enclosed and efficient scroll compressor with built-in safety protection, low noise, power saving and durable

2. High-efficiency shell-and-tube heat exchanger, using the latest technology, small size, high performance, not easy to damage, built-in high-pressure liquid reservoir to achieve no loss in the system and ensure smooth oil return

3. The chiller condenser adopts water cooling method, which can be used on various systems, not limited by ambient temperature, stable performance and convenient maintenance

4, equipped with a single-chip microcomputer control system, built-in compressor dryer filter and expansion valve, maintenance hand valve interface and other devices to ensure reliable and safe operation of the machine, convenient maintenance and repair. Compressors Compressors are imported from DAIKIN, SANYO, Copeland and other famous brand fully-enclosed scroll compressors, which are 20-30% more energy efficient than reciprocating compressors. It has the advantages of stable and reliable operation, high efficiency and low failure, low vibration and low noise, and convenient maintenance. According to customer needs and the size of the cold tonnage, a single compressor or a combination of multiple compressors can be used. Compressors can automatically and alternately operate according to load changes, balancing the hours of operation of each compressor, achieving the effects of saving energy consumption and extending the life of the chiller. Hermetic scroll compressors are available in a variety of refrigerant refrigerants such as R22, R407c, and R134a. Shell and tube condenser and evaporator The condenser uses different types of heat exchange copper tubes imported from Germany and Japan and domestically produced. The outer surface of the copper tubes is processed into trapezoidal low-rib tubes to increase the heat exchange area and enhance the heat exchange performance. The inner surface of the copper pipe is smooth, which reduces the water pressure and is easy to clean and maintain. The evaporator uses internally threaded, highly efficient copper tubes. The spiral outer surface of the copper tube is smooth and the water-side baffle adopts a non-short circuit design, which improves the mixed heat exchange efficiency of frozen water.

Freezing accessories

The refrigeration accessories are selected from Danfoss, ALCO, SPORLAN, etc., which are of the highest quality in the world, with high quality and excellent performance. Electric control system The electric control system adopts highly intelligent PLC and PC-level microcomputer control system. Responsive, accurate control, with multiple functions such as automatic loading and unloading, timing switch on and off, and recording the cause of failure, and can achieve remote or central monitoring.

Unit product quality is safe and reliable

Each unit is tested strictly in accordance with the national standard test items and tested by a full performance test device approved by the National Compressor Refrigeration Equipment Quality Supervision and Inspection Center. All performance indicators meet or exceed the requirements of national standards. Leave the factory

Unit configuration is complete and complete

The unit has completed all assembly, factory test and calibration of safety control devices in the factory, and has been charged with refrigerant. The end user only needs to connect the waterway and the circuit to put it into use, minimizing the installation and commissioning time on site

There are many varieties and specifications of the unit, and the application is wide

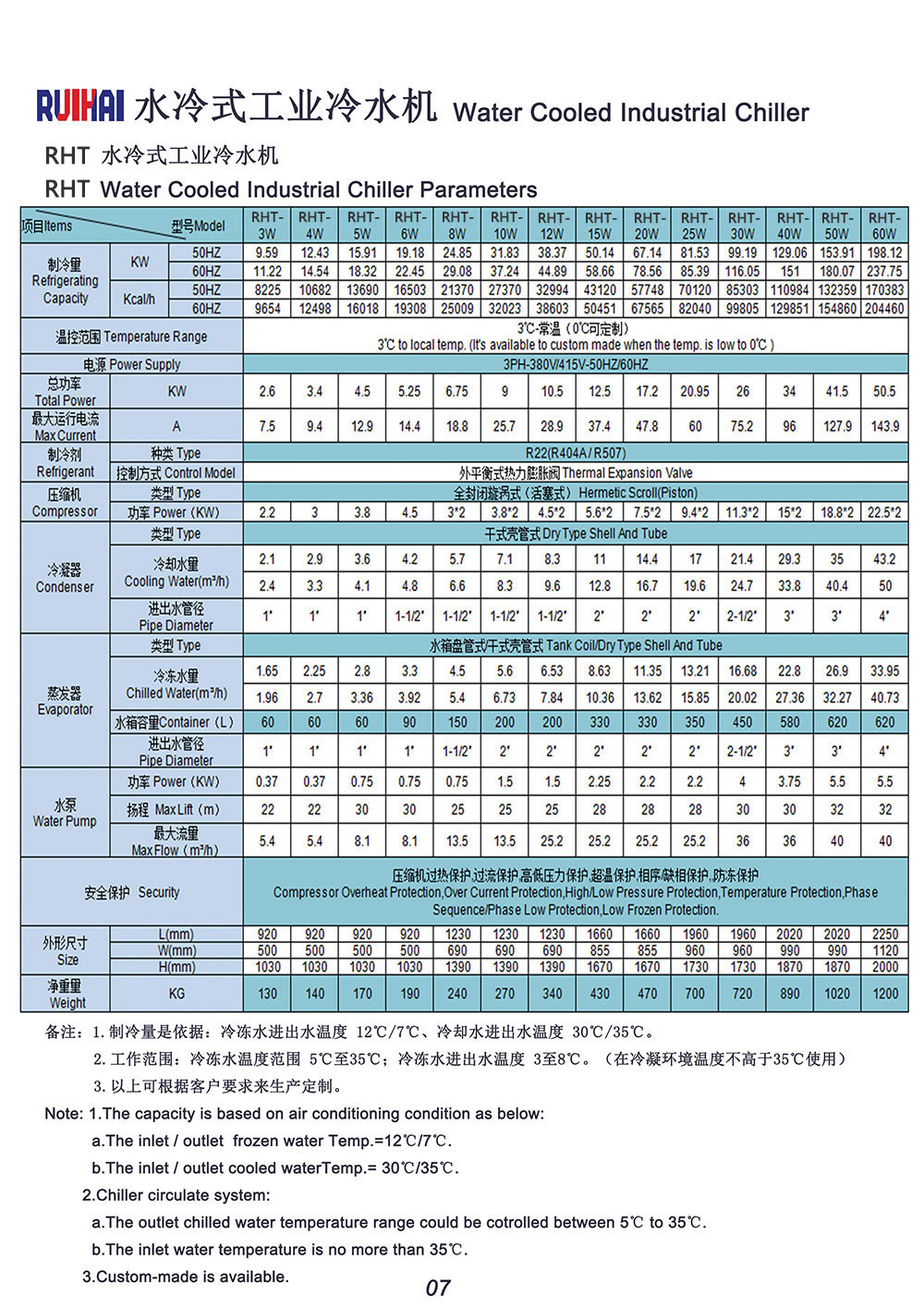

There are thirteen specifications of the unit series products, and the cooling capacity is from 9.5KW to 186.5KW.

Suitable for

1. Central air conditioning in various industries

2. Mold cooling in the plastics industry

3. Electroplating industry plating tank cooling

4. Ultrasonic cleaning liquid cooling

5. Various cooling in chemical industry

6. Various cooling for food industry

7. Cooling in metallurgy, petrochemical, machinery, medicine, electrophoresis, aluminum oxidation industries

8. Printing, artificial leather, vacuum coating, wallpaper and other industries

9. Cooling constant temperature of dust-free workshops in various industries

A good after-sales service

The warranty period is 12 months, free maintenance during the warranty period, only material cost fees are charged outside the warranty period.